Heat Press Machines [Compare Brands, Side By Side] Hobby - High Production

Heat Press GuideA heat press is the KEY piece of equipment in any customization shop. That’s true for home-based businesses, small shops and the biggest custom t-shirt and promo products businesses in the industry. Decorators need a heat press to accompany the various machines they use for customization. The most popular custom t-shirt, gift and promo products machines, like direct to garment printing, white toner transfers, heat transfer vinyl and sublimation all require a heat press. Using a good quality heat press is a great way for decorators and shop owners to ensure the correct time, temperature and pressure needed for a substrate. A few early tips in this heat press guide to find the best one for you? Look for:

ColDesi has customers that do almost every kind of decoration, so we offer a variety of heat presses to best fit your needs and budget. And we have the expertise to make sure you pick the right one. In this article, we’ll discuss the basics about heat presses and what you need to know before choosing one of your own. |

| What is a heat press? Known as the foundation for a successful customization business, a heat press is a machine that imprints designs and artwork to substrates such as t-shirts, using heat and pressure. As mentioned before, this is a must have machine in any customization business, especially for t-shirts. The part of the heat press that conducts heat is called the platen. In standard flat heat presses, the top platen is heated and can be adjusted to a lower or higher temperature depending on what the job calls for. Time and pressure are also both important components of a heat press and how it works. Using the correct time, temperature and pressure will help create amazing products for your business, however for each substrate there are different presets that need to be utilized. If you’ve been in the decoration business for a long time, then you are most likely familiar with what time, temperature and pressure is needed for different processes and substrates. The size of your heat press will also play a fundamental role in your decision-making process. Depending on what decorating process you choose and how big you plan for your business to be will correlate with what heat press you choose. However, we’ll quickly list the most common sizes of heat presses on the market.

It’s important to note that most transfer sizes are either 8.5” x 11” or 11” x 17.” I f you are in the t-shirt customization process, the ideal heat press size is 16” x 20,” because t-shirts can usually be decorated with larger transfers. Now let's talk about what a heat press is used for. |

|

|

What are heat presses most commonly used for? There are many reasons heat presses are used in customization businesses, whether it’s to decorate a t-shirt, mug, mousepad, baseball and many other items. Heat presses are used to permanently apply a heat transfer to a substrate. For substrates that aren’t apparel, there are different heat presses specifically made to customize them. Compared to an iron, heat presses have a much larger pressing area and help businesses achieve a more professional look. Below, we list some of the most common medias used with a heat press.

Flat heat presses are used to decorate apparel items such as t-shirts, jackets, jerseys, coasters, tote bags and much more! For non-apparel items like mugs, hats and sports balls there are heat presses specially designed with platens to properly place and hold these items under heat. For example, if you want to customize hats for a baseball team, you will need a hat press like the Hotronix 360 IQ Hat Press to achieve the job. This can’t be done with a flat press because the platens aren’t designed to properly hold a hat in place. Although, some heat presses have interchangeable platens, giving you the ability to switch when pressing on items such as an arm sleeves, pant legs, koozies and much more. We’ve touched a little bit on different heat presses but let’s dive deeper into the specific kinds. |

What are the different kinds of heat presses? First things first, one of the key differences between heat presses is if they are manual or automatic. Manual heat presses require you to open and close them yourself. Automatic heat presses will pop open by themselves after the timer goes off. Like we’ve briefly discussed, there are heat presses designed for different substrates and processes. For now, we will go over a few of the most common types of heat presses seen in a customization shop. Clamshell Heat Presses Just like the name implies, clamshell heat presses open and close like a clam due to a hinge between the upper and lower platens with the heat usually sourcing from the top. These are the most common heat presses and are used to press on items such as t-shirts, tote bags, flags and much more. Some clamshell heat presses have an auto-open capability, like the Geo Knight 16x20 Auto Clamshell. As a reminder, this means after the timer is finished, the upper platen will pop up by itself. Since curing a shirt takes a longer time in the heat press, this automatic style is ideal for direct to garment printers. Once the shirt is in the heat press, you won’t have to stand by it the entire time, allowing you to work on the next t-shirt. However, clamshell heat presses can be used for other decorators as well. Here are some pros and cons of the clamshell style heat press. Pros:

Cons:

Clamshell presses are usually some of the most affordable heat press machines on the market, which is why you may consider adding one to your shop. Of course, keeping in mind the pros and cons. Let’s chat about another one of the most popular machines, the drawer style heat press. |

|

|

Drawer Heat Press Drawer style heat presses are another one of the most common machines seen in many shops. Designed to help remove the hazard of burning from the upper platen, drawer heat presses allow you to pull the bottom platen out towards you. One of the great things about these heat presses is that it creates a safe work surface with less heat. Here at ColDesi, our staple and favorite drawer heat press is the Hotronix Fusion IQ. It’s a best seller due to its versatility and functionality. With Digital HeatFX white toner transfers, this particular heat press is ideal. The pull-out bottom platen aids in the “marrying” step of creating white toner transfers. This is also ideal for heat transfer vinyl and sublimation. The Hotronix Fusion IQ is an all-in-one press with a time, temperature and pressure read out, like most drawer heat presses are. You can easily save presets and switch back and forth from each for different projects. Many of the drawer heat presses like the Fusion IQ can use interchangeable platens and are manual. Below, we list some pros and cons of the drawer style heat presses. Pros:

Cons:

Swing away heat presses are next on our list for discussion. |

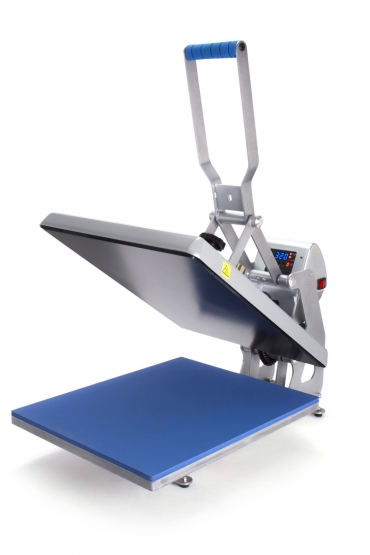

Swing Away Heat Press Once again, the design of these heat presses is implied in the name itself. In this case, it’s called the swing away heat press. Designed with the ability for the upper platen to “swing away” from the bottom platen, these heat presses are known for operator comfort. The upper platen on a swing away heat press moves up first, then to the left or right from the bottom platen. Since the heating element is the upper platen, this gives you a workspace free of burns. You can work on a variety of different items with a swing away heat press regardless of how thick the material is. If you want a heat press that will work well for almost any technique of printing, swing away models like the Digital Knight 16x20 Swinger or the Hotronix Fusion IQ will do the job. Now let’s take a look at the pros and cons of a swing away heat press. Pros:

Cons:

Swing away heat presses are offered as manual and automatic. It’s up to you to choose what method works best for the job you will be doing. Lastly, we’ll chat about hover heat presses. |

|

|

Hover Heat Press Hover heat presses like the Hotronix 16x20 Hover Heat Press are great for direct to garment printing, screen printing and heat transfer applications. The hover feature cures direct to garment designs without smearing the ink. When set in hover mode, this heat press will help the moisture from the pretreat sink into the shirt and prevent stiffness or shininess. This also prevents pretreat and ink residue from getting on your platen. The Hotronix hover heat press can also be switched back to its clamshell design for heat transfer applications, making it a versatile machine for any business. However, the hover feature is not necessary unless you are in the business of direct to garment printing, which is why this is a staple for many of these DTG shops. Pros:

Cons:

Now that you know a bit more about the different kinds of heat presses, we can get into the brands that offer them. |

What are the major brands of heat presses? Knowing who you are purchasing your heat press from is extremely important in this process. ou always want to make sure you do enough research on the company and check reviews from previous buyers to help you decide. One of the most important aspects of knowing the brand is what support they offer. Picture this, you purchase your first heat press and everything seems to be working in the beginning. However, since you’re new to the customization business, you have a few questions. Maybe you’re having trouble with marrying your white toner transfers or maybe you can’t figure out how a certain feature on your press works, what do you do now? If you purchased your heat press from a company and manufacturer that have reliable customer service and technical support, this will be no problem. When you purchase a heat press from ColDesi, we offer support from our knowledgeable and reputable customer care representatives and technicians who have extensive years of experience in the customization field. We’ve come up with a list of three of the most popular heat press brands in no particular order, with most of them being sold on our wholesale supply website, colmanandcompany.com

Making sure to pay attention to the quality and support will ensure that you have chosen a heat press suited best for you. Speaking of quality, let’s dive into what some of them are when you’re in the process of purchasing a heat press. |

|

|

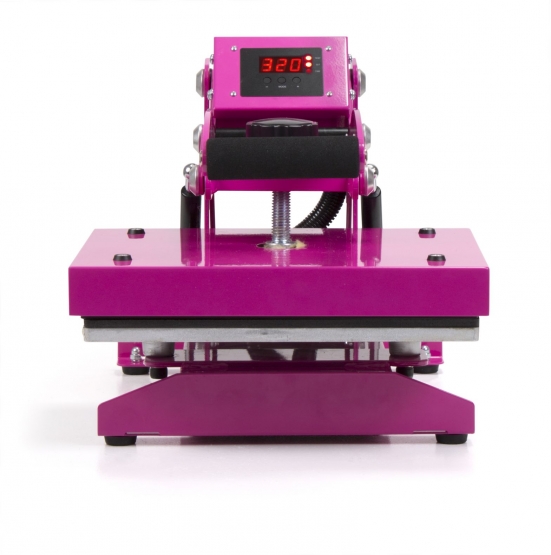

What are some qualities to look for in a heat press? Temperature and pressure accuracy are a few of the key components in the search for a heat press. Along with these components, you should also pay attention to durability. This goes across the board for all the decorating techniques and processes. Let’s briefly go over why each of these are important. Temperature - Ensuring accurate temperature on your heat press should be one of the first things you look for. To ensure even heating, it is standard for heating elements to measure no more than 2 inches apart. For consistent results, your heat press must have an even temperature across the entire surface of the platen to avoid peeling or washing off. Since most customizations take about 320 degrees Fahrenheit to adhere properly to a substrate, you will want to make sure it can reach that temperature. Most heat presses do reach that temperature but it’s always good to double check. Heat presses that are more expensive tend to have better heat quality than those that are cheaper. This is mostly due to the recovery time from each time you press. This means that the more expensive heat presses will recover to the set heat, eliminating unnecessary waiting time. Pressure – Accurate pressure is another key quality to look for in a heat press. When uneven pressure is distributed within a heat press, this will result in a destroyed garment or substrate. To avoid damaging your work, most heat presses have an adjustable knob to increase or decrease the amount of pressure being applied. Some heat presses like the Hortonix Fusion IQ also feature a digital time, temperature and pressure display which is helpful for getting accurate readings and even applications. When working with rhinestones and spangles, this is especially important. Durability – A well-constructed heat press will make you feel better about making such a big investment. You want to make sure that your heat press will last you for a long period of time, which means that taking the extra steps in searching for a high quality, well-built heat press will be worth it. Heat presses that have a steel frame are known for their durability, but the same can be said with a heat press made with a cast aluminum alloy frame. The only difference between the two is that cast aluminum alloy frames are lighter in weight. Keep in mind, just because a heat press is heavier than another, doesn’t mean it’s better or more durable. If you ever encounter a time where your heat press needs a new part or repair, we recommend having a machine with warranty and that is manufactured in the United States. Parts are easier to find and readily available when you purchase a machine that isn’t foreign. With all of this in mind, you might be wondering about how much this investment will be. Your budget will determine what machine to go for, which is what we’ll talk about next. |

How much should you spend on a heat press? Whether you decide to go for a more basic heat press or higher budget heat press, these will both depend on how big you want your business to be. If you are a hobbyist or smaller scale business, most heat presses will run between $300-$500. These are going to be the more affordable and compact heat presses that aren’t designed for mass production. Some examples of these machines include the Craft 9x12 Heat Press or the Geo Knight Jet Press 12 Light Duty Heat Press. Heat presses like these are lightweight and portable, which are both ideal for noncommercial usage. It also gives you the opportunity to test your new business for a small investment. If you are already in the customization industry and have a larger scale business, investing in a higher quality, more expensive heat press is the answer. You can usually find these more robust machines for about $1,000-$3,000. One that we’ve mentioned a few times for good reason is the Hotronix Fusion IQ, which we carry for $2,450 on our website. Another great heat press machine is the Digital Knight 16 x 20 Auto Clamshell. This one runs for $1,550 on our website and is great for direct to garment printing. Now, you will find some heat presses above this price range, however these usually have extra attachments such as lasers, platens and more. We understand that purchasing a heat press can be a huge investment, which is why we offer financing. Let’s walk you through what that looks like with ColDesi. |

|

|

Can you finance a heat press? The answer to this is yes, you can finance a heat press. It’s no secret that your finances are the most important aspect of your business and is key in any decisions you make. With our partners at QuickSpark, we make the financing process simple and easy with the following steps:

Approvals for financing can go from anywhere between $1000 to $100,000. One of the great things about working with QuickSpark is that even if you have low credit or you are just starting your business out, they have multiple solutions and programs for every situation. If you’re still hesitant on financing, here are a few reasons why it’s beneficial. With the ability to get brand new equipment for low monthly payments, you can start selling your custom products and generate enough revenue to pay your first installment before it’s even due! QuickSpark also offers payment plans ranging anywhere between 12 to 60 months, which can help keep your payment low and comfortable for your business. Another great advantage of financing is Section 179 of the IRS code. So, what does this mean? Designed to help small businesses, Section 179 allows you to deduct the full purchase price of the equipment the same year you bought it. In fact, most businesses are able to deduct 100% of the total equipment costs. With all these benefits like jump starting your business and saving you money on taxes, it becomes a no brainer as to why most of our customers decide to finance. Factors like building credit also play a huge role in this decision. You can always live chat with one of our pros if you have any additional questions. To help you even further, we’ll talk about where to purchase your heat press from. |

Where should you buy a heat press from? We’ve given you plenty of information about heat presses that you need to know and consider before purchasing one. Now is the time to go ahead and make your first business investment. At ColDesi, we offer high quality machines, blanks, supplies and support to help boost and expand your business. When you purchase with us, you get exclusive access to our training courses, Custom Apparel Startup group and rewards programs. We also help you set up your supply account and give you tours to all of the resources you will need in your customization journey. We help set your business up for success by putting it first with every interaction we have. You can join the ColDesi family today by calling (877) 793-3278 and live chat with one of our pros. We hope this helped ease any worries you may be having about purchasing your first heat press and we look forward to welcoming you into the world of customization! You can find more articles on heat press machines here. |

|